One vehicle, countless components.

Modern vehicles typically comprise around 30,000 components, all of which manufacturers must ensure they perform reliably under every condition.

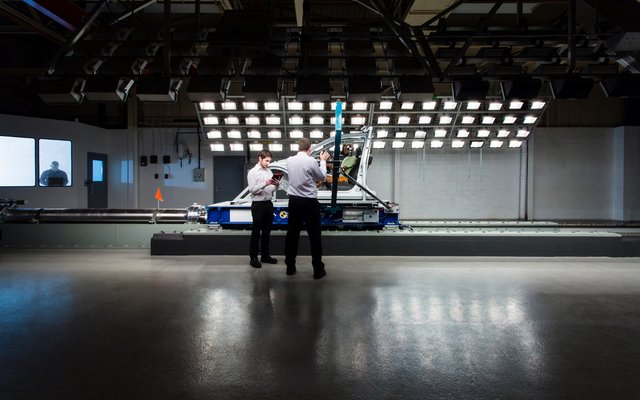

We support you throughout the entire process, from development and type approval to production monitoring, by providing comprehensive component testing. Our extensive range of environmental, hydraulic, and electromagnetic test benches is available across three locations in France and the UK: Mortefontaine, Leyland, and Millbrook.

What we offer

Extensive Testing Capabilities

- Environmental testing with precise control of temperature, humidity, and sunlight exposure

- Endurance testing using both synthetic signals and real track data reproduction

- Vibration testing on hydraulic and electromagnetic shaker tables

- Dynamic and static characterization tests, including testing to failure

- Squeak and rattle assessments to detect unwanted noises in vibration-prone parts

- Closure tests of vehicle components (doors, boots, armrests, etc.) using pneumatic jacks

At UTAC, we have the capability to test all types of components under a wide range of environmental conditions. Our versatile facilities and expert teams ensure reliability, safety, and performance in every scenario.